Call us: +86 0518-87284110

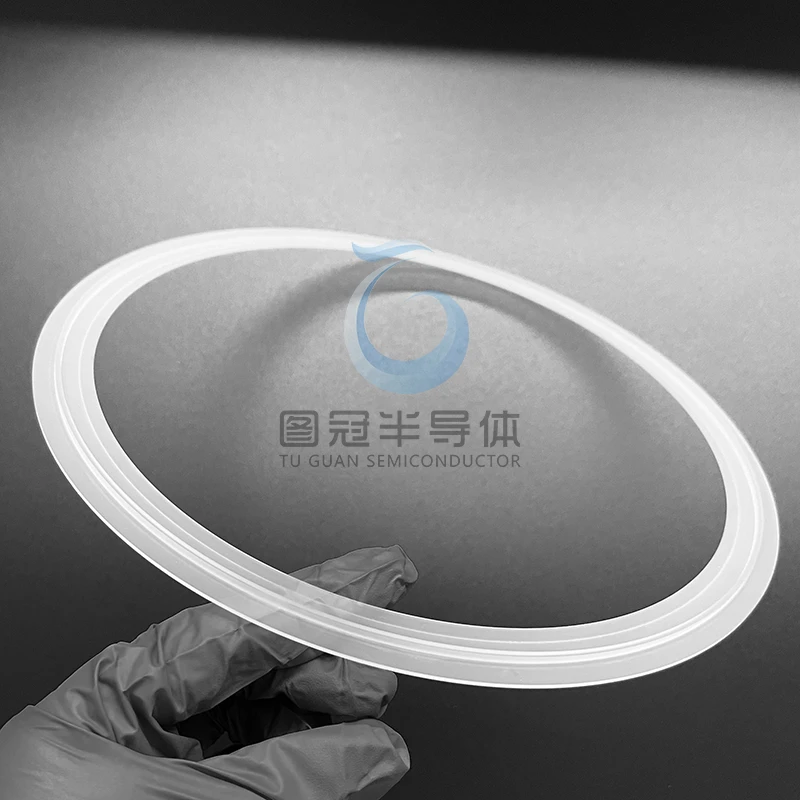

Fused Quartz Rings & Process Components

Fused quartz rings and process components engineered for semiconductor, plasma etch, and vacuum applications. Machined from high-purity fused silica to your drawing, these parts provide excellent thermal stability, chemical inertness, and precise dimensional control—ideal for sealing, spacing, shielding, and handling in high-temperature, corrosive environments.

What to Provide for a Quote

- Drawing (PDF/STEP) or key dimensions: OD / ID / thickness; any steps, lips, or ledges

- Function & interface: sealing land width/finish, ring-to-part gap, mating parts (tube, plate, door, chuck)

- Features: bolt pattern (BCD, hole qty), countersinks/counterbores, alignment notches/keys, vent holes, o-ring grooves

- Optional elements: standoffs/posts, pockets, shadow/lip geometry, splash shields, laser part ID/orientation mark

- Operating conditions: vacuum level/pressure, plasma/chemistry, max temperature, cleanliness target

- Critical tolerances: flatness, parallelism, concentricity/runout; required surface quality on functional faces

- Quantity (prototype or batch), inspection reports needed, packaging level

Key Specifications

- Material: High-purity fused quartz (SiO₂); material certificate available by request

- Geometry: Flat rings, stepped/double-lip rings, donut plates with openings, rings with standoffs/posts or integrated shields; monolithic or flame-fused assemblies

- Dimensions: Per drawing (made-to-order); uniform section thickness for thermal stability

- Edges & Surfaces: Fire-polished rims; ground or polished sealing/viewing surfaces; smooth radii to minimize particle generation

- Mounting & Alignment: Precise bolt circles, countersinks/counterbores, dowel features; optional laser marking

- Cleanliness: Ultrasonic/DI cleaning; Class-100 compatible packaging

- Variant: Opaque (OP) quartz available when additional thermal shielding is required

Material Properties (Typical)

- Very low thermal expansion, good thermal-shock tolerance

- Excellent chemical resistance to most process media (note: HF attacks quartz)

- Electrically insulating, low outgassing; optically clean where transparency is needed

Processing & Design Notes

- Define sealing land width/finish and any o-ring groove geometry to hit the target leak rate

- Vent blind or threaded holes that see vacuum to prevent virtual leaks

- Keep wall thickness uniform and add generous internal radii to reduce stress

- Standoffs/posts improve spacing and airflow; specify height/diameter and tip finish

- We can advise feasible tolerances for flatness, parallelism, concentricity, and runout based on size and geometry

Inspection & Testing

- Dimensional verification: OD/ID/thickness, step heights/widths, bolt circle, hole Ø/positions; post/standoff height

- Flatness/parallelism checks of sealing and reference faces; runout vs. datum

- 100% visual inspection for chips, micro-cracks, inclusions, and contamination

- Optional: helium leak test (assembly), surface finish verification, birefringence/stress evaluation, cleanliness report

Applications

Sealing rings for furnace/tube ends and vacuum doors, spacer/support rings, splash/particle shields, alignment and handling rings, ring-shaped protective plates for etch, CVD/PECVD, diffusion/oxidation, wet-bench and metrology subsystems

Packaging & Storage

Edge guards and separators; anti-static, vacuum-sealed packaging with rigid outer protection. Store dry (<40% RH) at 10–30 °C and away from HF-containing chemicals.

Notes

Custom configurations (hole patterns, coatings, or additional markings) available upon request.

Compliance certificates (RoHS, ISO 9001) provided with bulk orders.