Call us: +86 0518-87284110

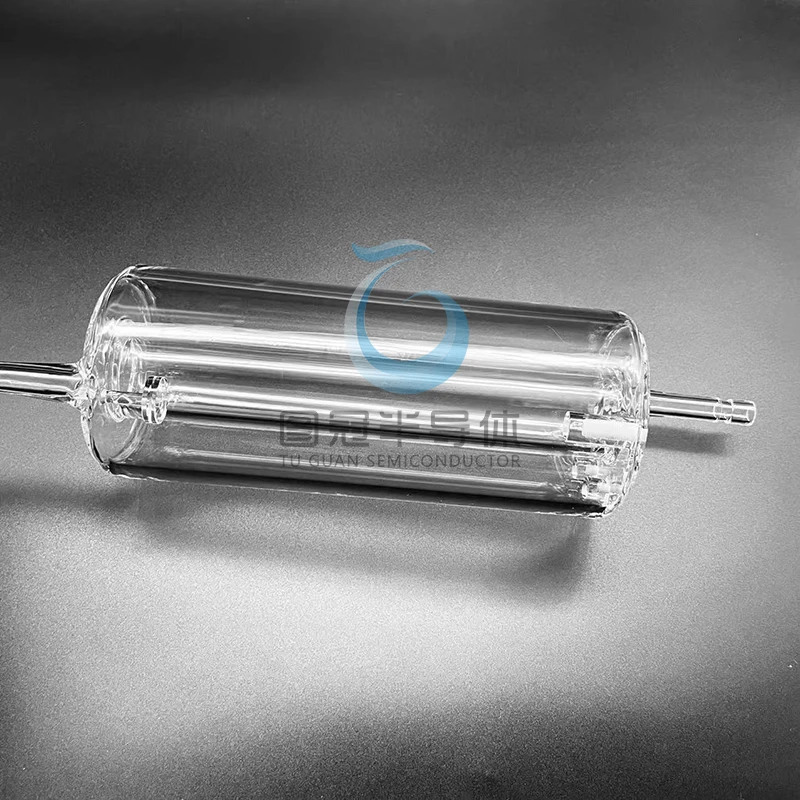

Fused Quartz Reactors, Heat Exchangers & Bubblers

Custom fused quartz reactors, heat exchangers, and bubblers engineered for semiconductor tools, chemical processing, and laboratory use. Built from ultra-high-purity fused silica and assembled by precision flame-fusion, these complex components provide outstanding chemical resistance, thermal stability, and clean, precise fluid/vapor handling in vacuum and high-temperature environments.

What to Provide for a Quote

- Drawing (PDF/STEP) or key dimensions and layout (tube OD/ID/lengths, coil or bundle geometry, vessel size)

- Process conditions: gases/chemicals, max temperature, vacuum level/allowable pressure, target flow rates and heat load

- Connection types: ground glass joints, ball/socket, KF/ISO/CF flanges, or custom adapters

- Internal features: dip tube length, sparger/multi-hole diffuser, baffles, coils/jacket, thermowell/sight ports

- Critical tolerances: concentricity, straightness, parallelism, leak rate specification

- Quantity (prototype or batch), inspection reports needed, packaging/cleanliness level

Key Specifications

- Material: High-purity fused quartz (SiO₂); material certificate available by request

- Configurations:

Reactors: straight or jacketed vessels, multi-port manifolds, integrated coils or baffles

Heat exchangers: coil, serpentine, or tube-in-tube styles; multi-tube bundles; inlet/outlet manifolds

Bubblers: single or dual-port designs with internal dip tube/sparger; vapor outlet above liquid level - Connections: Standard taper joints, ball/socket, KF/ISO/CF flanges, hose barbs, or custom terminations

- Assembly: Precision flame-fused joints and transitions; stress-relief annealing available

- Surface & Cleanliness: Smooth, chip-free edges; ultrasonic/DI cleaning; Class-100 compatible packaging

- Design Limits: Per drawing; intended for vacuum or low-pressure service—pressure ratings defined by design and test plan

Material Properties (Typical)

- Exceptional chemical inertness (note: HF attacks quartz)

- High thermal stability with very low thermal expansion

- Electrically insulating, low outgassing; optically clean surfaces suitable for high-purity service

Processing & Design Notes

- Use generous radii at junctions to reduce stress and particle traps

- Add vents to avoid virtual leaks in vacuum paths; specify desired leak-rate target

- Coil pitch, tube spacing, and wall thickness should reflect required heat transfer and pressure drop

- For bubblers, define liquid level, dip-tube immersion depth, and desired bubble size (sparger type)

- Choose joint/flange standards to match downstream equipment and maintenance practice

Inspection & Testing

- Dimensional verification (tube OD/ID/lengths, coil geometry, port positions)

- Helium leak test by request (vacuum service); optional flow/pressure hold test per design

- Birefringence/stress check, visual inspection for chips, cracks, inclusions, and contamination

- Cleanliness verification and packaging certificates available

Applications

ALD/CVD precursor delivery (bubblers), vapor generation and scrubbing, heat exchange in corrosive or high-purity lines, micro-reactors, laboratory and pilot-scale processing

Packaging & Storage

Anti-static, vacuum-sealed packaging with shock-absorbent foam and rigid protection for fragile appendages. Store dry (<40% RH) at 10–30 °C. Keep away from HF-containing chemicals.

Notes

Custom configurations (hole patterns, coatings, or additional markings) available upon request.

Compliance certificates (RoHS, ISO 9001) provided with bulk orders.