Call us: +86 0518-87284110

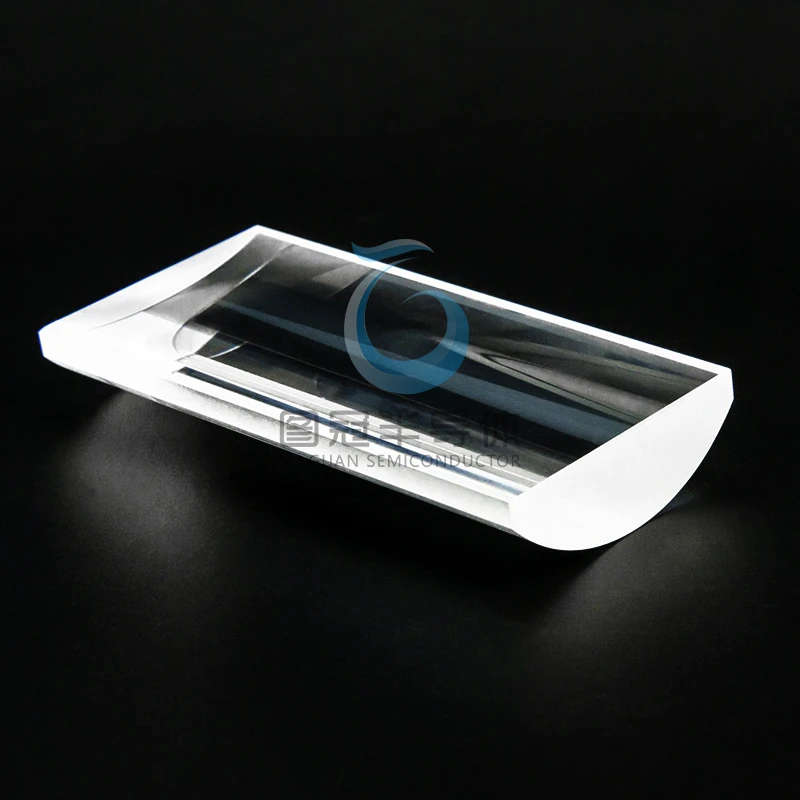

Fused Quartz Plano-Convex Lenses & Optical Elements

Custom plano-convex (PCX) lenses—spherical or cylindrical—and related optical elements made from high-purity fused silica. Engineered for UV systems, laser optics, and semiconductor equipment, they combine excellent UV transmission, very low thermal expansion, and robust thermal stability for precise light shaping and reliable performance in demanding optical paths.

What to Provide for a Quote

- Drawing (PDF/STEP) or target optics: type (spherical/cylindrical), focal length or radius of curvature, clear aperture, overall size

- Thicknesses: center thickness (CT), edge thickness (ET), wedge requirement, bevel size (safety chamfer)

- Surface specs: figure (power/irregularity), surface quality (scratch-dig), flatness for plano face

- Tolerances: centration/decenter, parallelism, dimensional tolerances, orientation marks if cylindrical

- Coatings (optional): AR/HR/bandpass; wavelength band and angle of incidence

- Environment: operating temperature, laser power/fluence (if relevant), cleanliness level

- Quantity (prototype or batch) and any required inspection reports

Key Specifications

- Material: High-purity fused quartz / fused silica; UV-grade available on request

- Forms: Plano-convex spherical lenses, plano-convex cylindrical lenses, windows, wedges, prisms per drawing

- Dimensions: Made-to-order; round or rectangular apertures; clear-aperture and edge treatment as specified

- Surfaces: Optical polish on functional faces; plano face polished/ground per spec; fine ground sides with protective bevels

- Coatings: Custom AR from deep-UV to NIR; single- or multi-band options; coating on one or both sides

- Cleanliness: Ultrasonic/DI clean; Class-100 compatible packaging; laser ID/orientation marks available

Material Properties (Typical)

- High internal transmission from UV through visible (grade-dependent)

- Very low CTE and excellent thermal-shock resistance

- Chemically inert to most media (note: HF attacks quartz)

- Low fluorescence and low outgassing for sensitive optical paths

Processing & Design Notes

- Specify whether focal length is at design wavelength and in air; provide radius sign convention

- For cylindrical lenses, indicate cylinder axis and any clocking marks; define clear-aperture zone

- Balance figure/roughness with cost: tighter scratch-dig and λ/figure specs increase polishing time

- Choose coatings to match wavelength band, AOI, and laser damage threshold; define durability standard if needed

- Add generous safety bevels to minimize edge chipping and particle generation

- Thermal cycling: allow compliant mounts to accommodate small dimensional changes

Inspection & Testing

- Interferometric measurement of figure (power/irregularity) and plano flatness

- Spectrophotometric transmission and AR reflectance tests (on request)

- Centration/decenter via auto-collimator; wedge/parallelism verification

- Surface quality (scratch-dig) and cosmetic inspection; coating adhesion/durability per requested spec

- 100% visual check for chips, digs, inclusions, and contamination

Applications

UV illumination and imaging, beam shaping and line focusing (cylindrical lenses), laser delivery and metrology, optical windows and viewports in semiconductor tools

Packaging & Storage

Lint-free wraps and protective caps; each optic in cushioned, dust-free clamshell with desiccant. Store at 10–30 °C, <40% RH. Handle with powder-free gloves; avoid contact with HF-containing chemicals.

Notes

Custom configurations (hole patterns, coatings, or additional markings) available upon request.

Compliance certificates (RoHS, ISO 9001) provided with bulk orders.