Call us: +86 0518-87284110

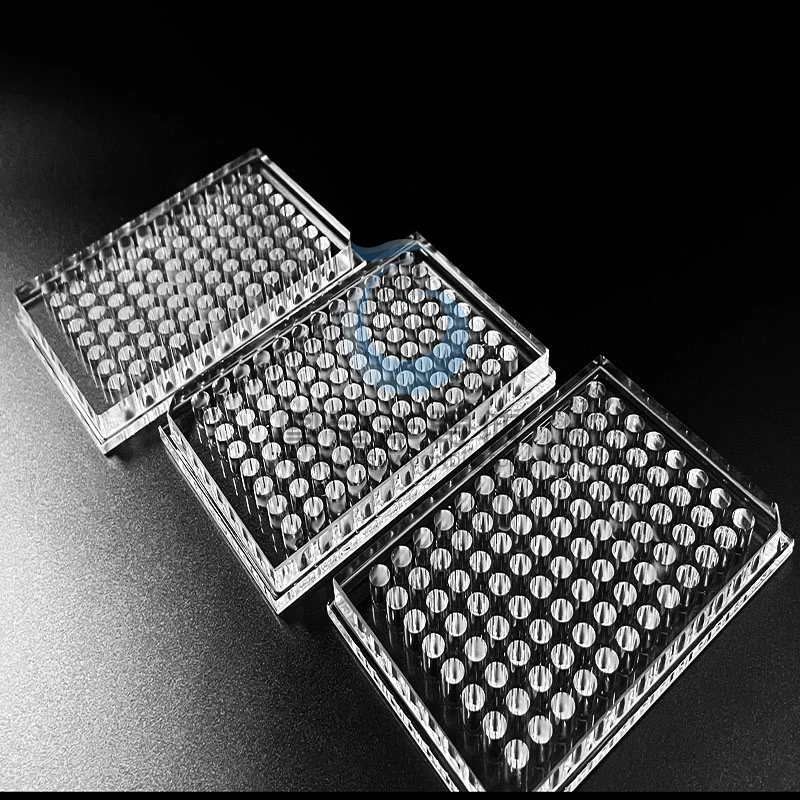

Fused Quartz Microplates & Multi-Well Assay Plates

Fused quartz microplates for high-throughput assays, ELISA, fluorescence/absorbance readouts, and other sensitive bio/chemical analyses. Built from high-purity fused silica, these plates provide exceptional UV transparency, very low autofluorescence, chemical inertness, and tight dimensional control for reliable, contamination-free results with modern plate readers.

What to Provide for a Quote

- Drawing (PDF/STEP) or format: 96 / 384 / 1536 wells, SBS footprint, skirt type (skirted / semi / low profile)

- Well geometry: flat / U / V / conical bottom; well Ø, pitch, depth; wall and bottom thickness; corner radius

- Optical requirements: transmission band (e.g., UV 200–400 nm), surface polish, bottom flatness for imaging, allowable autofluorescence

- Surface options: native quartz, hydrophilic/hydrophobic treatment, silanization or anti-adsorption coatings (by request)

- Identification & handling: A1 orientation mark, barcode/2D code, fiducials, alignment features, cover/film type

- Operating conditions: solvents/chemicals, temperature range/thermal cycling, cleanliness/sterility level

- Critical tolerances: well pitch/position, bottom thickness uniformity, plate flatness/warp

- Quantity (prototype or batch), inspection reports needed, packaging level

Key Specifications

- Material: High-purity fused quartz (SiO₂); UV-grade fused silica available by request

- Formats: SBS-compatible 96/384/1536-well plates; custom well count/layouts; single-well quartz view plates

- Geometry: Cylindrical or tapered wells; flat/V/U bottoms; through-plate windows for imaging; optional quartz lids/covers

- Surfaces: Optical-polished well bottoms for high NA imaging; ground/polished edges; deburred, chip-free wells

- Cleanliness: Ultrasonic/DI cleaning; Class-100 compatible packaging; optional pre-cleaned or bagged-by-lot

- Construction: Monolithic or bonded quartz assemblies; stress-relief annealing available

Material Properties (Typical)

- High internal transmission from deep-UV to visible (grade-dependent)

- Extremely low autofluorescence and low extractables; excellent chemical resistance (note: HF attacks quartz)

- Very low CTE and good thermal-shock tolerance; electrically insulating and low outgassing

Processing & Design Notes

- Define optical path length (well bottom thickness + fill height) for accurate absorbance calculations

- Specify imaging area size/flatness for microscopy; polish only the zones that impact measurement to optimize cost

- Keep well pitch per SBS standards for reader compatibility; maintain uniform bottom thickness to reduce focus drift

- Add fiducials/barcodes and A1 corner to assist automation; consider anti-adsorption coatings for protein assays

- For bonded designs, select adhesive-free fused joints or low-outgassing bonding per application

Inspection & Testing

- Dimensional verification: footprint, plate height, well count/position, pitch, Ø, depth, bottom thickness

- Flatness/warp check across the plate; edge and corner quality inspection

- Optical tests on request: UV/Vis transmission at key wavelengths (e.g., 230/260/280 nm), autofluorescence benchmarking, surface roughness of bottoms

- 100% visual inspection for chips, digs, inclusions, and contamination; cleanliness certification by lot if required

Applications

ELISA and absorbance assays, fluorescence and luminescence readouts, cell-based imaging on quartz windows, DNA/RNA and protein quantification in UV, high-purity chemistry screens, analytical and microfluidic experiments

Packaging & Storage

Lint-free trays with cavity separators; vacuum-sealed or cleanroom-bagged packaging; optional lot labeling and barcodes. Store at 10–30 °C, <40% RH. Handle with powder-free gloves; avoid contact with HF-containing chemicals.

Notes

Custom configurations (hole patterns, coatings, or additional markings) available upon request.

Compliance certificates (RoHS, ISO 9001) provided with bulk orders.