Call us: +86 0518-87284110

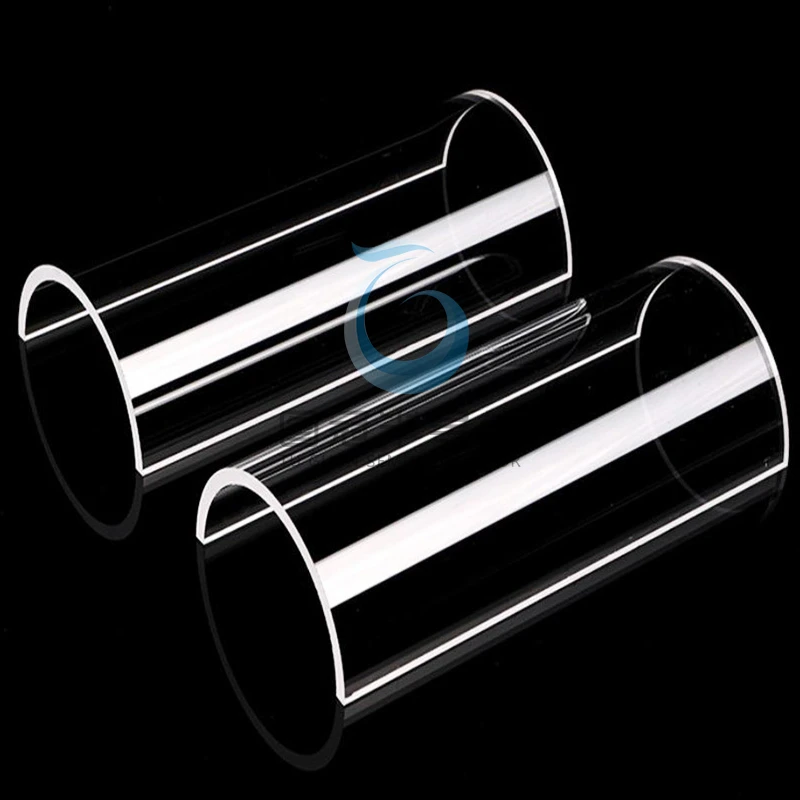

Fused Quartz Curved Plates & Furnace Tube Liners

Fused quartz curved plates and half-tube liners engineered for high-temperature, high-purity environments in semiconductor tools, chemical processing, and industrial furnaces. Manufactured from high-purity fused silica with smooth, chip-free edges, these parts provide excellent thermal stability, chemical inertness, and precise fit—offering reliable protection, clean flow, and long service life.

What to Provide for a Quote

- Drawing (PDF/STEP) or key dimensions: inner/outer radius (or tube ID/OD), arc angle (e.g., 90°/120°/180°), length, thickness

- Geometry: single curved plate, half-tube, quarter cylinder, or segmented liner; overlap or butt joint style

- End & edge details: square/rounded ends, lips/flanges, tabs, chamfer/bevel; any slots, holes, or windows

- Interface & fit: mating tube or frame size, target liner-to-wall gap, contact/landing areas, mounting or clamp method

- Operating conditions: chemistry, maximum temperature and thermal cycling, vacuum/pressure (if any), cleanliness level

- Critical tolerances: profile/radius accuracy, straightness, parallelism, roundness/runout along the arc

- Quantity (prototype or batch); requested inspection reports and packaging level

Key Specifications

- Material: High-purity fused quartz (SiO₂); material certificate available by request

- Geometry: Curved plates, half-tube liners, quarter-sections, split sleeves, and custom arc segments—monolithic or flame-fused assemblies

- Dimensions: Per drawing (made-to-order) with uniform wall thickness for thermal stability

- Edges & Surfaces: Fire-polished rims; ground or polished functional faces; smooth radii to minimize particle generation

- Optional Features: Relief/vent holes, alignment notches/keys, o-ring grooves or sealing lands, locator tabs

- Variants: Opaque (OP) quartz available for added thermal shielding; clear fused quartz for visual inspection

- Cleanliness: Ultrasonic/DI cleaning; Class-100 compatible packaging

Material Properties (Typical)

- Very low thermal expansion with good thermal-shock tolerance

- Excellent chemical resistance to most process media (note: HF attacks quartz)

- Electrically insulating, low outgassing; optically clean where transparency is required

Processing & Design Notes

- Define whether radius is referenced to the inner or outer surface; keep wall thickness uniform to reduce stress

- Allow expansion gaps and compliant clamping to avoid stress during thermal cycling

- Add generous fillets at transitions and deburr all edges to prevent chipping and particle traps

- For segmented liners, specify joint overlap/spacing and any anti-rotation features

- We can advise feasible tolerances for radius/profile, flatness/straightness, and runout based on size and geometry

Inspection & Testing

- Dimensional verification: radius/arc angle/length/thickness; profile tolerance along the arc; hole/slot positions

- Flatness/straightness checks on reference lands; roundness/runout relative to datum

- 100% visual inspection for chips, micro-cracks, inclusions, and contamination

- Optional: birefringence/stress evaluation and cleanliness report

Applications

Furnace tube liners and split sleeves, thermal shields and splash guards, protective baffles, curved windows or guides for high-purity, high-temperature processes (diffusion/oxidation/CVD, wet benches, and lab furnaces)

Packaging & Storage

Edge guards and curved separators; anti-static, vacuum-sealed packaging with rigid outer protection. Store dry (<40% RH) at 10–30 °C; keep away from HF-containing chemicals.

Notes

Custom configurations (hole patterns, coatings, or additional markings) available upon request.

Compliance certificates (RoHS, ISO 9001) provided with bulk orders.