Call us: +86 0518-87284110

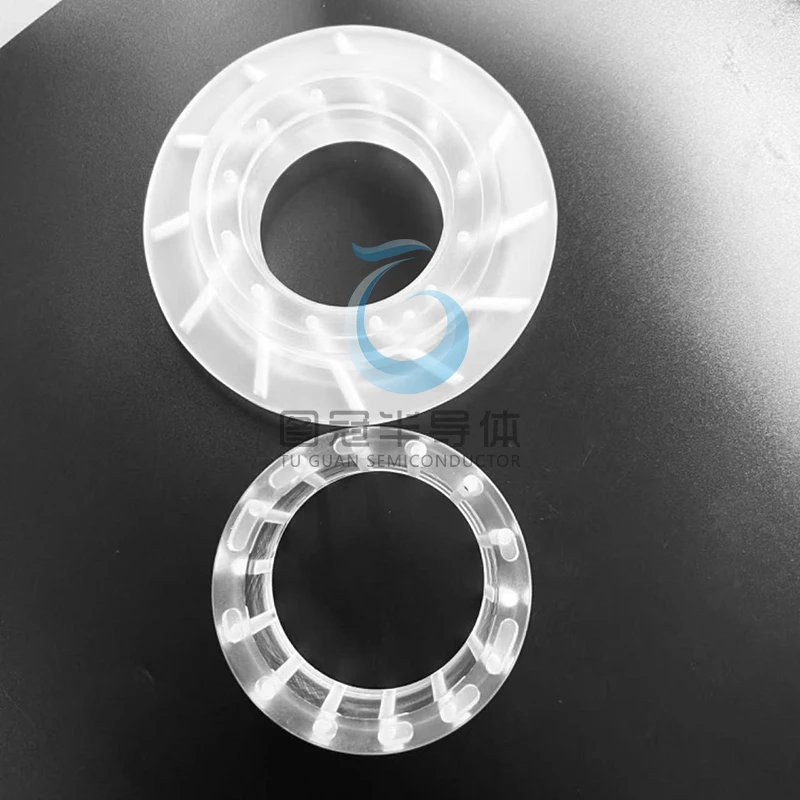

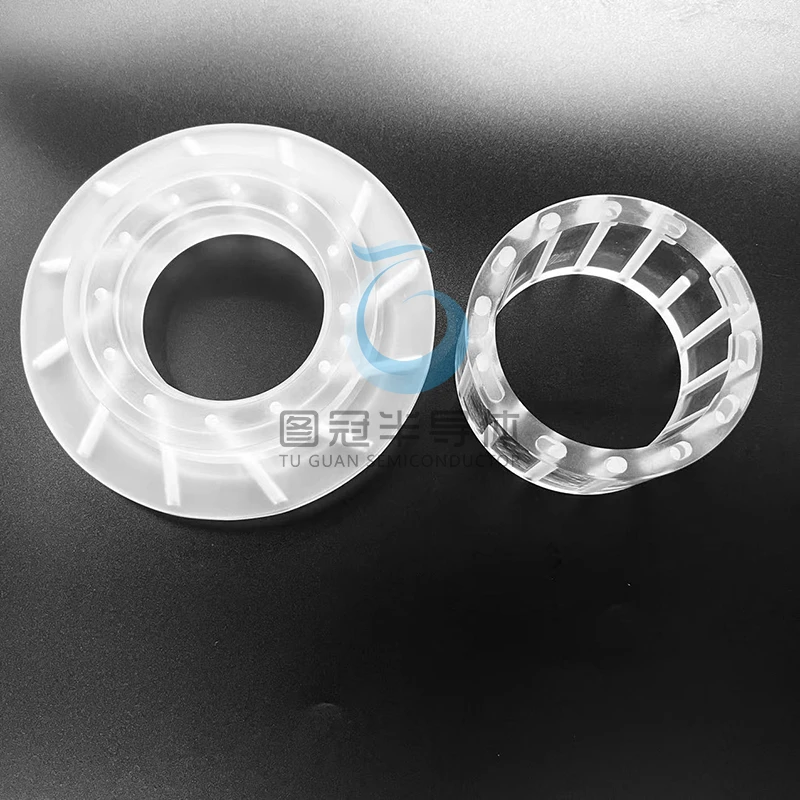

Precision Fused Quartz Support Rings & Process Components

Fused quartz support rings and process components designed for semiconductor manufacturing, plasma etching, and other high-temperature, high-purity environments. Machined from high-purity fused silica and optimized for stiffness and flow, these parts provide excellent thermal stability, chemical inertness, and precise dimensional control—ensuring reliable support, spacing, and process flow.

What to Provide for a Quote

- Drawing (PDF/STEP) or key dimensions: OD / ID / thickness; any steps, lips, or ledges

- Function & interface: mating parts (chuck/plate/tube), target ring-to-part gap, sealing/landing areas

- Features: bolt circle and hole size/quantity; countersink/counterbore; alignment keys/notches; vent/drain holes

- Flow & stiffness details: ribs/slots/stand-offs (height/spacing), weight-reduction pockets, airflow path requirements

- Operating conditions: vacuum/plasma chemistry, max temperature, cleanliness target

- Critical tolerances: flatness, parallelism, concentricity/runout; surface finish of functional faces

- Quantity (prototype or batch), required inspection reports, packaging level

Key Specifications

- Material: High-purity fused quartz (SiO₂); material certificate available on request

- Geometry: Flat or stepped rings; double-lip/ledge styles; rings with ribs/slots/stand-offs; donut plates with openings; monolithic or flame-fused assemblies

- Dimensions: Per drawing (made-to-order) with uniform section thickness for thermal stability

- Flow & Support Features: Radial ribs and longitudinal slots for controlled gas flow and stiffness; evenly spaced vent holes to prevent virtual leaks and improve purge efficiency

- Edges & Surfaces: Fire-polished rims; ground/polished functional faces; smooth radii to minimize particle generation

- Alignment & Mounting: Precise bolt patterns, countersinks/counterbores, dowel features; optional laser part ID/orientation mark

- Variant: Opaque (OP) quartz available where additional thermal shielding is needed

- Cleanliness: Ultrasonic/DI cleaning; Class-100 compatible packaging

Material Properties (Typical)

- Very low thermal expansion and good thermal-shock tolerance

- Excellent chemical resistance to most process media (note: HF attacks quartz)

- Electrically insulating, low outgassing; optically clean where transparency is required

Processing & Design Notes

- Keep wall thickness uniform and use generous internal radii to reduce stress concentration

- Define landing width/finish and any o-ring groove geometry to achieve target leak rate if used for sealing

- Vent blind/threaded holes that see vacuum to avoid virtual leaks

- Ribs/stand-offs improve stiffness and spacing—specify height, thickness, and spacing; add weight-reduction pockets where mass is a concern

- We can advise feasible tolerances for flatness, parallelism, concentricity, and runout based on size and geometry

Inspection & Testing

- Dimensional verification: OD/ID/thickness, step heights/widths, rib/slot spacing, bolt circle and hole positions

- Flatness/parallelism checks on reference and sealing faces; runout vs. datum

- 100% visual inspection for chips, micro-cracks, inclusions, and contamination

- Optional: helium leak test (assembly), surface finish verification, birefringence/stress evaluation, cleanliness report

Applications

Support and spacer rings on chucks/plates, flow-conditioning and purge rings for plasma/CVD tools, splash/particle shields, alignment and handling rings for wafer/process carriers in high-temperature or corrosive environments

Packaging & Storage

Edge guards and separators; anti-static, vacuum-sealed packaging with rigid outer protection. Store dry (<40% RH) at 10–30 °C; keep away from HF-containing chemicals.

Notes

Custom configurations (hole patterns, coatings, or additional markings) available upon request.

Compliance certificates (RoHS, ISO 9001) provided with bulk orders.