Call us: +86 0518-87284110

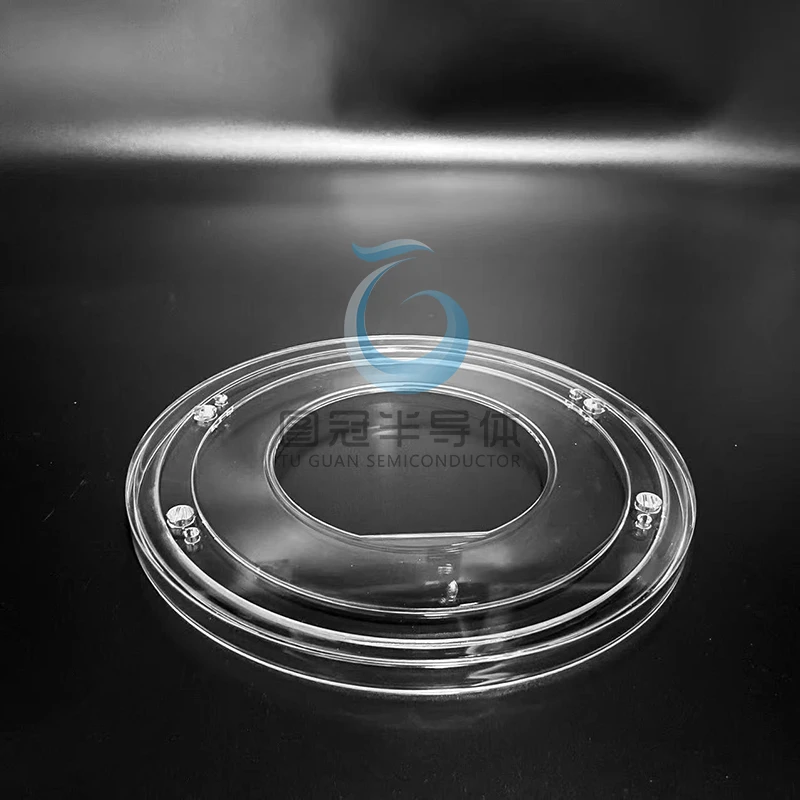

Fused Quartz Ring Covers & Protective Plates

Fused quartz ring covers and protective plates for semiconductor equipment, vacuum systems, and optical assemblies. Manufactured from high-purity fused silica and machined to your drawing, these clear components deliver excellent optical clarity, thermal stability, chemical inertness, and precise fit—providing reliable sealing, splash protection, and visual access in sensitive environments.

What to Provide for a Quote

- Drawing (PDF/STEP) or key dimensions: outer Ø, inner Ø/opening, thickness

- Bolt pattern: bolt-circle Ø (BCD), hole Ø/quantity, slot or clearance style, countersink/counterbore details

- Sealing features: o-ring groove size/position, sealing land width/finish, gasket interface

- Functional options: sight window zone, raised/stepped rims, alignment notches/keys, vent holes to avoid virtual leaks

- Operating conditions: vacuum level/pressure, chemicals, temperature, cleanliness target

- Critical tolerances: flatness, parallelism, concentricity/runout; surface quality on sealing and optical areas

- Quantity (prototype or batch), inspection reports required, packaging level

Key Specifications

- Material: High-purity fused quartz (SiO₂); material certificate available on request

- Geometry: Round or polygonal ring covers, donuts, full plates with central aperture; single-piece or multi-piece assemblies per drawing

- Dimensions: Per drawing (made-to-order); uniform section thickness for thermal stability

- Edges & Surfaces: Fire-polished rims; ground/polished sealing lands and viewing surfaces to minimize particles and improve seal integrity

- Mounting & Alignment: Precise bolt patterns, countersinks/counterbores, dowel/locator features; optional laser part ID/orientation mark

- Cleanliness: Ultrasonic/DI cleaning and Class-100 compatible packaging

Material Properties (Typical)

- Excellent chemical resistance to most process media (note: HF attacks quartz)

- Very low thermal expansion and good thermal-shock tolerance

- Electrically insulating, low outgassing; high optical clarity for viewing/alignment

Processing & Design Notes

- Define sealing land width/finish and o-ring groove geometry to meet target leak rate

- Add venting on blind features that see vacuum to prevent virtual leaks

- Use generous internal radii and deburred edges to reduce stress and particle generation

- We can advise feasible tolerances for flatness, parallelism, concentricity, and runout based on size/geometry

Inspection & Testing

- Dimensional verification: OD/ID/thickness, bolt-circle, hole Ø/position, groove size/position

- Flatness and parallelism checks of sealing and optical surfaces

- 100% visual inspection for chips, micro-cracks, inclusions, and contamination

- Optional: helium leak test (assembly), surface finish verification, cleanliness report

Applications

Chamber covers and viewports, ring-shaped protective plates, splash shields for wet benches, vacuum door interfaces, optical and alignment plates in metrology or lithography subsystems

Packaging & Storage

Edge guards and protective films on optical/sealing areas; anti-static, vacuum-sealed packaging with rigid outer protection. Store dry (<40% RH) at 10–30 °C; keep away from HF-containing chemicals.

Notes

Custom configurations (hole patterns, coatings, or additional markings) available upon request.

Compliance certificates (RoHS, ISO 9001) provided with bulk orders.